How does Changxi Packaging Technology (Yixing) Co., Ltd ensure high barrier properties and functionality when producing Building Waterproof and Heat-insulating Tube Film?

1. Multi-layer co-extrusion technology ensures high barrier properties

Changxi Packaging uses multi-layer co-extrusion blown film technology to produce building waterproof and heat-insulating films. This technology is the core to achieve high barrier properties. Multi-layer co-extrusion films are composed of multiple functional layers. The materials of each layer have different functions and properties. By combining these layers together, the overall barrier properties of the film can be effectively enhanced. Changxi's multi-layer co-extrusion technology can achieve high barrier properties of film materials in the following ways:

Selection of high barrier materials: Changxi selects raw materials with excellent barrier properties, such as high-density polyethylene (HDPE), low-density polyethylene (LDPE), polyester (PET), etc. These materials can effectively isolate moisture, gas and steam penetration, and prevent moisture, mold or thermal effects caused by gas leakage inside the building. In addition, these materials can also enhance the physical strength of the film material and improve the durability of the film layer.

Hierarchical structure optimization: Through multi-layer co-extrusion, Changxi can stack materials with different functions together to enhance the barrier properties of the film. For example, the outer layer uses anti-ultraviolet and anti-aging materials to improve the weather resistance of the film; the inner layer uses polymer materials with excellent gas and water vapor barrier properties. The combination of layers ensures that the overall barrier properties of the film meet industry standards through precise technology and equipment, which can effectively prevent moisture penetration and air circulation, and ensure the waterproof performance of the building.

Airtightness and impermeability: Changxi's multi-layer film structure can provide excellent airtightness to prevent moisture, humidity, etc. from penetrating into the interior of the building. Especially in the application of building waterproof and heat insulation film, airtightness and impermeability are important guarantees to prevent the building structure from getting damp and reduce energy loss.

2. Research and development and innovation of functional packaging materials

In addition to high barrier properties, building waterproof and heat insulation films also need to have certain functionality to meet application requirements in different environments. Changxi Packaging continuously improves the functionality of its products through continuous technical research and development to ensure the long-term reliability of building waterproof and heat insulation films in various complex environments.

Thermal insulation function: Building waterproof and thermal insulation films must not only have excellent waterproof properties, but also excellent thermal insulation functions, especially under extreme climate conditions such as high temperature and low temperature, the energy consumption of buildings needs to be effectively controlled. Changxi uses specific materials in multi-layer films (such as aluminum foil layers with thermal insulation properties or special functional coatings) to introduce heat reflection or thermal insulation layers into the film materials, which can effectively block the penetration of external heat while maintaining the stability of the internal temperature of the building. This technology greatly improves the energy efficiency of building membranes and reduces the energy consumption of building air conditioning and heating systems.

Anti-ultraviolet performance: Building membranes are often exposed to outdoor environments, and exposure to ultraviolet rays may cause the membrane materials to age, fade or deteriorate in performance. Changxi packaging uses special anti-ultraviolet coatings or adds raw materials with anti-ultraviolet functions to enhance the anti-ultraviolet ability of membrane materials. This not only extends the service life of the membrane, but also ensures that the building waterproof and thermal insulation film can still maintain good waterproof and thermal insulation effects during long-term use.

Anti-corrosion and weather resistance: In outdoor environments, building waterproof membranes need to resist wind and rain, temperature changes and chemical erosion. The high-quality raw materials and coatings used by Changxi have strong corrosion resistance and weather resistance, and the membrane materials can maintain their excellent functionality even after long-term exposure to harsh environments. By using high-temperature resistant and anti-aging materials, Changxi ensures that the building waterproof and heat-insulating tube film can cope with various harsh environmental conditions.

3. Strict quality control system

In order to ensure the high barrier and functionality of Building Waterproof and Heat-insulating Tube Film, Changxi Packaging has established a strict quality management system. The company has passed ISO9001 quality management system certification, QS quality and safety certification, and complies with US FDA standards. These international certifications provide strong guarantees for the quality and safety of the membrane materials produced by the company. Each batch of products must pass strict testing and verification procedures to ensure that its performance meets industry standards.

Fully enclosed, high-cleanliness production workshop: Changxi's production workshop adopts a fully enclosed, high-air cleanliness production environment to prevent any external pollutants from affecting the quality of the membrane materials. During the production process, the temperature, humidity, air cleanliness, etc. in the workshop are strictly controlled to ensure that the manufacturing of each layer of the membrane meets the ideal standard.

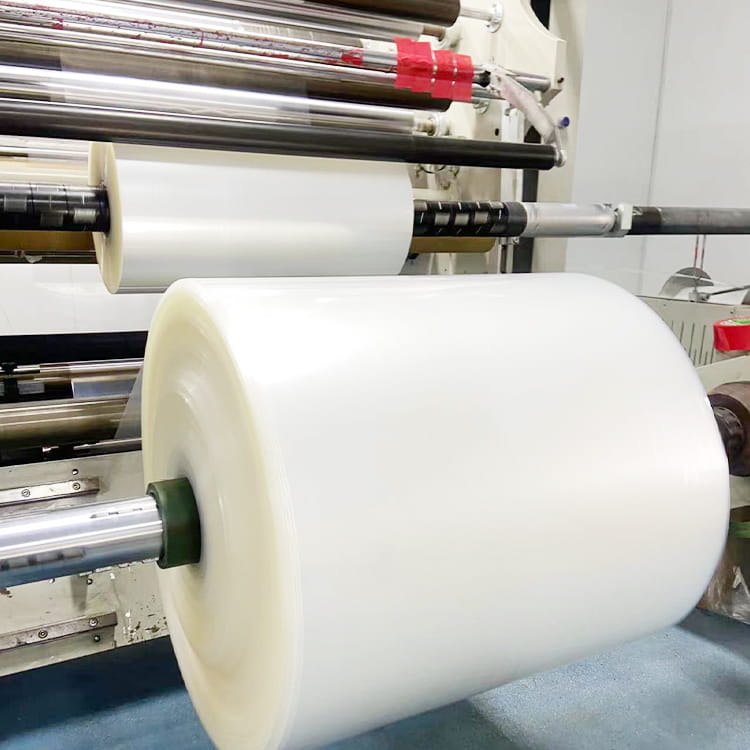

Fully automated production lines and high-precision equipment: Changxi has 4 multi-layer co-extrusion blown film production lines, multiple high-speed slitting units, and fully automated bag-making production lines to ensure that every link in the production process can achieve high-precision control. From the selection and processing of raw materials to the packaging of the final product, the entire process is strictly carried out in accordance with the requirements of the quality management system to ensure the stability of each film product in terms of waterproofing, heat insulation and functionality.

Performance testing and quality monitoring: Changxi conducts strict performance testing on each batch of film materials, including tensile strength, barrier properties, thermal isolation effect and other indicators. The company is also equipped with advanced testing equipment, such as air tightness testers, thermal flow meters, ultraviolet accelerated aging testers, etc., to ensure that the various performance of the products meet the design requirements, and the film materials finally delivered to customers have excellent quality and performance.

English

English عربى

عربى